New project proposal BeFORE

BeFORE (Barrier for recycling)

Following the REPAC² project, which will continue until the end of 2023, the project partners have already started the construction of a new possible follow-up project. This new project proposal was named BeFORE (Barrier for recycling).

The abstract of this new and international project proposal can be seen in the text below.

For more information, please feel free to contact info@pack4food.be

Project title

Recyclable material innovations for ’contact sensitive’ plastic and paper packaging with high quality barrier properties

PROJECT SCOPE

Need and problem

Multilayer plastic and paper packaging play a key role in protecting sensitive products during shelf life. However, high-barrier packaging materials as complex multi-material structures (Alu; met; PVDC; EVOH; PVAL; PA) are excluded from the mechanical recycling path and/or may hinder the recycling of other materials in waste streams. Sorting and mechanical recycling are primary processes to valorise used packaging. While chemical recycling is evolving quickly and will become increasingly important in coming years, it is currently not economical and is not widely accepted. With the European demand to have all packaging reusable or recyclable by 2030, material selection is focused on mono-materials. Recommendations on refusing or limiting metal and polymer barrier layers are critical to qualify packaging as single-material, sortable and recyclable with available technologies. These assumptions lead to the supply of quality secondary materials for circular applications. Limiting the use of these essential barrier materials in packaging puts pressure on the functionality of the barrier, creating a need for other high-quality barrier materials that are regaining interest and newly developed, to comply with current recycling guidelines.

This allows to change the paradigm of multi-layer packaging with a barrier layer inside the structure and evolve towards packaging with thin functional coatings fulfilling barrier requirements. "Barrier" is an umbrella term, multiple factors are included: gas (oxygen, carbon dioxide, volatile compounds (e.g. aroma, fragrance) or other gases), moisture, liquid (water, oil, acid) and light/UV transmission.

Other barrier coated materials, such as AlOx- based, PEN, LCP or organic-inorganic hybrid barrier structures could serve as a solution. Also new materials are being developed and show promising first results. However, optimizing and validating these materials for packaging concepts is needed in the sectors of food, petfood and cosmetics, who are the main users of multilayer packaging.

Innovation target

The main goal of this project is to improve design for recycling of primary packaging by studying the implementation potential of promising flexible packaging materials with alternative barrier materials. The creation of well-performing plastic and paper packaging, considered as mono-material, is encouraged to ensure good mechanical recycling. In this context, pre-treatments that can be implemented in mechanical recycling will be taken into account, such as deinking and washing. Groups of key parameters have been selected to measure technical aspects of product protection and packaging recyclability: static and dynamic mechanical properties, barrier properties and the sensory quality of the product, sealability, compatibility with automatic packaging systems and recyclability in existing streams. Economic feasibility and market availability will be considered in the assessment.

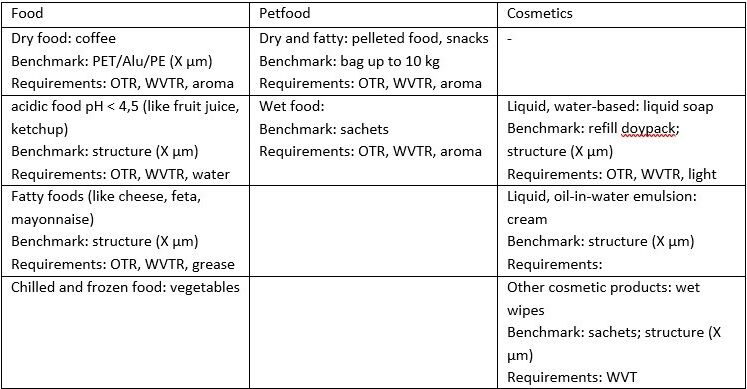

Three categories of products were selected for the research: food, pet food and cosmetics. Each category includes dry and moist products with different water/fat content and different storage characteristics. The physical and chemical structure of the product will constitute the test selection criteria.

Product type and packaging benchmark

Goals

To reach the innovation target, following sub-goals will be targeted;

- Alternative barrier materials are inventoried in the beginning and during the project + compliance is assessed with European legislation/new developments, with respect to paper packaging and single-use plastics

- Promising flexible packaging with alternative barrier materials will be screened and benchmarked against existing solutions

- 5 generic (3 plastic and 2 paper) packaging case studies will be defined in cooperation with the guidance group companies (e.g. coffee, tea, dry pet food, chocolate, meat, wet wipes, liquid soaps,…) where multilayer packaging is replaced with a promising alternative barrier packaging

- Promising barrier materials are applied on lab-scale plastic and paper packaging to assess relevant properties linked with the cases:

- Barrier properties: OTR, WVTR, grease/oil and light transmission,…

- Mechanical properties: crack-resistance (bendability), adhesion, strength, tear, puncture, friction , packaging line compatibility,…

- Chemical surface properties: sealability, printability,…

- Mechanical recyclability is tested according to the most recent recycling guidelines

- Assess how to be compliant with legislation on paper packaging and single-use plastics on the European market

- Strategic dissemination and communication are focussed on the companies in the value chain for accelerated uptake of project results; dissemination of results through scientific, peer-reviewed publications and presentation of research results for business.

Industry focus

The project will focus on the food, pet food and cosmetics (as they follow the food guidelines due to lack of own standards) industry. Companies in the guidance group for the value chain for coated packaging consists of material supplier, converter, packaging producer, food manufacturer as the packaging demands are defined by the food manufacturer based on the demands from the retailers, customers and legislation.

Project partners