CheckPack

Integrated optical sensors in food packaging

The aim of this research project is the development of an optical sensor in packaging films which on the one hand detects microbiological and chemical spoilage of food products, packaged under modified atmosphere. It also measures on the other hand the amount of CO2, present in those packages.

Packaging materials for food products become a major player in our society through their increasing functionality. They offer an appropriate protection towards the food products and an increased convenience towards the consumers. Furthermore, they play an essential role in providing information. Regarding the latter, different stakeholders within the food industry show an increased interest in food packaging providing direct information of the current quality status of the packaged food product. Such quality indicators preferably are integrated in the packaging material, are economically sustainable and show a correct representation of the quality status of the food products.

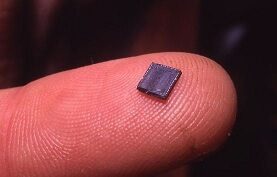

An optical sensor will be developed in this research project which reacts through a coating with specific volatile components, produced by microbiological or chemical spoilage processes in the food product. The selection of those specific volatile components will be based on the one hand on the expertise present within the project consortium of research partners. Further research on the other hand will be performed in this project to establish the relation between microbiological and chemical processes in the food products, storage conditions and produced volatile components. Through integrating this sensor on the inside of packaging materials, it will continuously measure the quality status of the packaged food product, starting from the packaging process until storage on the shelves in retail. The sensor can be read out at any time from the outside of the packaging material through an IR- reader device. The signal will be linked with the amount of volatile compounds adsorbed on the coating of the sensor and consequently linked with the quality status of the food product. Research on sensitive ánd specific coatings will lead to the development of an intelligent packaging concept enabling early-spoilage detection.

Such technology offers not only the advantage of being able to follow up the quality status of single packages through a non-destructive technique. It also give opportunities to remove packaged food products from the market, which are unacceptable for consumption, eventually leading to a

decrease in possible consumer complaints. Early spoilage of product defects also leads to a faster feedback towards the different stakeholders in the production and distribution chain resulting in increased efficiency to tackle the problem.

Furthermore, this research project aims to expand this multifunctional optical sensor with a detection unit for CO2, a gas frequently applied in food packaging as anti-microbiological component. Such MAP-packages (Modified Atmosphere Packaging) play an important role in the food industry as they can lead to major shelf life extensions without altering the intrinsic food properties. The on-line and non-destructive measurement of CO2-concentrations in food packaging will allow to determine very fast and accurate if the desired CO2-concentration is still present inside the packaging. This in turn gives information on the performance of the packaging machine (at level of food producer) and on the package integrity throughout the distribution chain.

This research project will initially focus on the meat- and fish industry which are two important food sectors in Flanders. Meat and fish products are furthermore very perishable through both microbiological and chemical processes because of their intrinsic properties. The majority of these product are packaged under modified atmosphere. A major disadvantage of this packaging methodology is the fact that quality assessment based on sensorial, microbiological or chemical analyses is not possible without opening the package. Both the food industry as well as the distribution chain need to tune their logistic chain on sampling plans and shelf life experiments, mostly at worst-case scenarios, which can result in large product volume losses and consequently in large economic losses. This research project therefore aims by means of the developed sensor to provide a tool for fast, accurate and non-destructive analysis of the quality status of packaged meat- or fish products in every stage of the distribution chain, starting from the packaging process at the food producer. These obtained concepts will be translated in further projects towards other food product groups (e.g. fruits and vegetables, biscuits) as well as the broad MAP-packaging sector; the latter because of the non-destructive and on-line analysis of CO2.

How can smart packaging reduce food waste?

Want to know more?